- OPMAATZAGEN.nl

- DIY tips

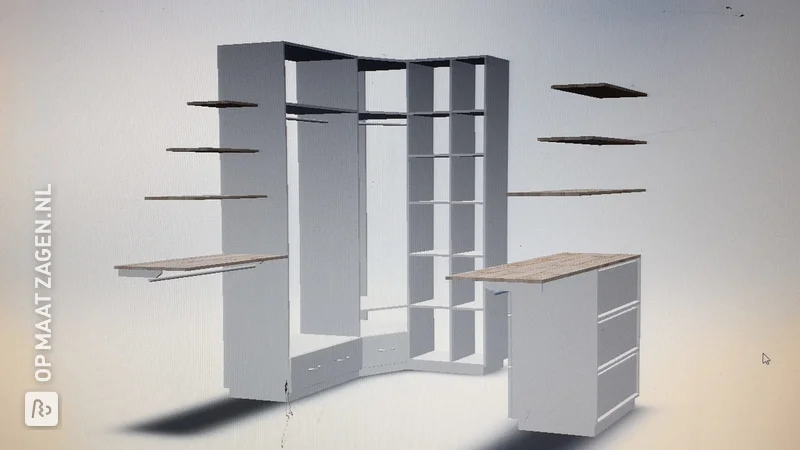

Sealing an open staircase yourself

Sealing an open staircase yourself

Closing an open staircase yourself is a fairly simple job. Especially with precisely cut-to-size timber from OPMAATZAGEN.nl. In fact, cutting the risers for the stairs is half the job. In this article, you can read exactly how to close your open staircase and we share examples from our handymen.

In this article:

- How do you close an open staircase?

- What items do you need to close an open staircase?

- How do you measure the size of the risers?

- How do you attach risers to stairs?

- Finishing the stairs

- What wood do you use to close an open staircase?

- Examples of sealed stairs from our handymen

- Get started sealing your own staircase

How do you close an open staircase?

Do you want to close your open staircase? There are several reasons for this. Maybe you think it is safer for your small children or you want to be less bothered by noises from upstairs or downstairs. Or maybe your motivation to close your staircase is purely cosmetic: it can also look very nice, after all!

In this article, we explain exactly how to seal an open staircase yourself. At OPMAATZAGEN.nl you order precisely cut-to-size wood for this job. Super handy, because then all you have to do is fit your stair risers!

What items do you need to close an open staircase?

To close an open staircase, you will need a number of items. Exactly what you need depends on how you want to approach your project. But keep the following in mind:

- Tape measure or laser range finder: for accurately measuring the risers

- Cordless drill: to easily pre-drill holes and screw the screws into the staircase

- Drill set with countersink: to hide the screws nicely

- Screws: use screws that sink nicely into the wood

- Wood glue and possibly dowels: may be needed to attach the risers to the steps

- Primer and varnish: Almost all timbers from OPMAATZAGEN.nl have yet to be finished - priming first, then varnishing

- Sandpaper: always handy to have on hand, with a coarse or small grain

- Router: if you want to make slots in the steps to insert the risers

What are risers?

Sealing an open staircase basically revolves around one thing: fitting risers between the steps and finishing them neatly. What are risers? Fenders are the vertical boards between the horizontal steps. Exactly what is still missing from your open staircase, in other words.

How do you measure the size of the risers?

The most important thing if you want to close an open staircase is to accurately measure the measurements of the risers. Do not assume that every riser is the same size, as there are almost certainly differences between stair treads.

Measuring the size of the risers is a precise job. Use a tape measure or laser gauge to do this. Measure from the back of the stairs. Start at the bottom step, measuring each gap one by one. You measure from the bottom of the step below to the bottom of the step above.

Write down the length and width measurements in mm on a piece of paper and make sure you know which measurements correspond to which steps. You can do this by numbering each step, e.g. from bottom to top.

You now have a list with the exact size in mm for each riser. With this list, you can order the wood exactly cut-to-size at OPMAATZAGEN.nl. This way, we take the hardest part of the job off your hands: cutting the risers to perfect size!

Tip: give each riser a number and state this when ordering. We will then deliver each riser with a sticker to you, so that you know exactly which part needs to be fitted in which place.

Also check out our article with fitting tips for more on fitting.

How do you attach risers to stairs?

You can use several methods for fixing risers on the open staircase. We discuss four of them here.

Directly Screwed into the Steps

First, drill holes for the risers and the stair treads. Hold the riser in place and screw in the screws one by one. Neatly finish the drill holes with putty or wood filler so that they are no longer visible.

Some of our DIYers, like Rick who closed this open staircase, use a special set (Wolfcraft undercover jig) to screw in the screws at an angle and sink them.

Using Slats

Another method is to first attach slats to the stair treads, like DIYer Hugo did with this staircase. Again, drill the screw holes first and then screw the risers onto them.

The advantage of this method compared to screwing directly into the stair treads is that you don't have to screw (at an angle) into the stair treads.

Using Dowels

Of course, you can also use dowels to create a sturdy connection between the stair treads and the risers. Drill the holes for the dowels with a dowel drill bit and apply a little glue to the dowels. This creates a very strong connection.

Routing and Screwing

If you have a router, you can choose to route a slot in the tread, where you let the riser fall into. At the top, screw the riser into the tread. Or you can do it exactly the other way around (like DIYer Ruben did with this open staircase): you route the top tread and let the riser fall into it. Fixing is not even necessary at the top anymore.

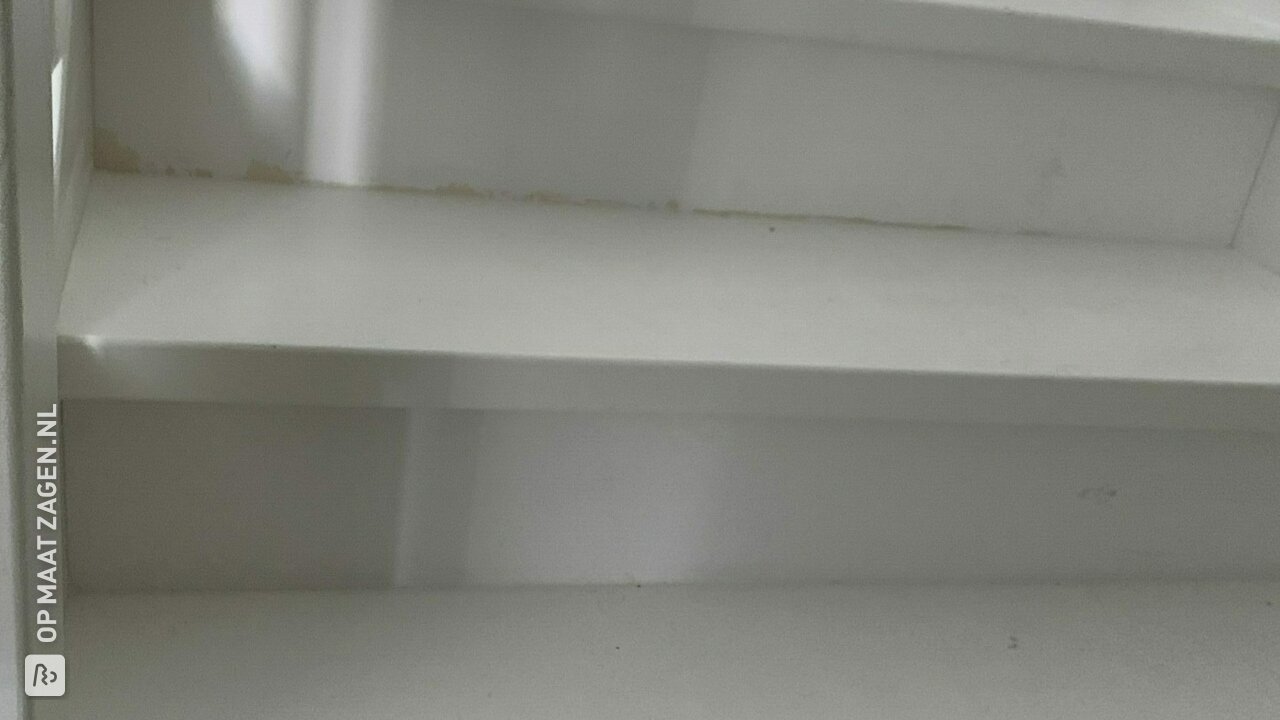

Finishing the Staircase

Once the risers are in place, the rest of this beautiful job awaits you: finishing the stairs and making it a beautiful whole.

To hide corners and seams neatly, you can use a polymer sealant. Apply the sealant not too thick and smooth it out neatly (with a finger with a little water and detergent or with a special sealant tool).

Fill the screw holes neatly with a paintable putty or wood filler and lightly sand them afterwards.

You achieve the most beautiful result by fully finishing the entire staircase with a staircase lacquer or oil after it has been closed.

Which type of wood do you use to close an open staircase?

To close an open staircase, you can use many different types of wood. The wood of the risers is not load-bearing and therefore does not need to be a structurally strong type of wood. However, you do want to use wood that can withstand some wear and tear, as the risers of the closed staircase will often be bumped into due to intensive use.

In the projects of our DIYers, we often see the use of the following types of wood:

MDF

MDF panels belong to the family of fiberboards. It consists of wood fibers compressed under high pressure. This makes MDF easy to work with. You can also choose MDF with a lacquer-carrying foil, which you don't have to prime yourself. That saves work!

Plywood

Plywood is a beautiful, strong sheet, consisting of different layers of wood veneer. The layers of plywood can consist of hardwood or softwood, such as birch, beech, poplar, or okoumé.

OSB

A material that we see more and more in various interiors is the rugged OSB. This gives your staircase a completely different, rugged look! OSB is relatively cheap and easy to work with.

Examples of closed stairs from our DIYers

Not sure yet how you want to close your open staircase? Then take a look at the projects of our DIYers. They have already done this job. Now you can be inspired by them.

Closed staircase with solid beech

DIYer Ruben closed this staircase with solid beech timber panels. He used a domino router to attach the risers. It has been neatly oiled to make the staircase one whole again.

A safe staircase for small children

If you have small children, an open staircase can be unsafe. DIYer Michel thought so too, so he closed his open staircase with 12 custom-cut plywood sheets. Michel drilled the screw holes with a countersink bit so that the screws disappear nicely into the wood.

Closing stair treads with pre-primed plywood

DIYer Koen realized that measuring the treads is quite a task when he wanted to close his staircase. He ordered pre-primed plywood from OPMAATZAGEN.nl, which made the painting work a lot easier.

Staircase covered with PVC

DIYer Hugo proves that you can also turn an open staircase into a stylish closed one. He covered his staircase with PVC after closing it. To prevent the stairs from creaking, he planed a piece off each riser - read more about this in his DIY project. The result is beautiful!

Staircase with plywood risers

DIYer Wilco used dowels to attach the plywood risers securely to the treads. In hindsight, he would have preferred to make the risers slightly shorter, but the result is still fine!

Staircase closed with primed MDF

You'll be finished more quickly with pre-primed MDF. DIYer Pascal experienced this when he covered his staircase with it. He chose to shorten the risers himself with a miter saw and attach each plank with countersunk 6x80 chipboard screws. After three coats of paint, the staircase looks beautiful!

Staircase made of OSB for a warm look

DIYer Sarah wanted a warm look and therefore opted for OSB risers. It looks really cool indeed.

Get started with closing your own staircase

In this article, we explained how you can close an open staircase yourself. The most important thing about this job is to measure the different stair treads properly. With the custom-cut wood from OPMAATZAGEN.nl, the rest of the job becomes a lot easier afterwards.

If you are going to work on your staircase yourself, we would appreciate it if you would also share your result with us. This way, you can also inspire other DIYers in turn.

Have fun closing your staircase!